Fill out the information and click the download button below to get our latest product brochure!

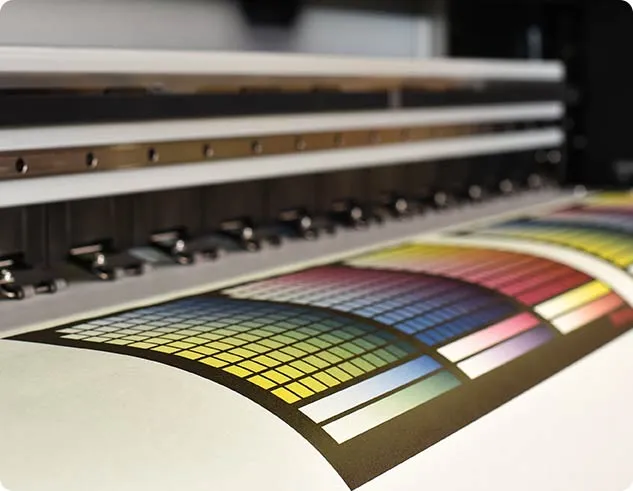

A laminating machine is an essential piece of equipment in industries that require high-quality, durable, and professional lamination for various substrates. The machine applies a protective layer of film to the surface of materials like paper, plastic, and textiles, enhancing their durability, appearance, and performance. Laminating machines are widely used in packaging, printing, and product finishing, ensuring that the end products are both aesthetically appealing and resistant to wear and tear.

Key Features:

- Versatile Performance: Suitable for a wide range of materials, including paper, plastic, and fabric.

- Efficient Production: Optimized for high-speed, high-volume lamination with minimal downtime.

- Adjustable Settings: Allows for customization of temperature, pressure, and speed to suit different substrates and lamination needs.

- User-Friendly Operation: Designed for easy setup and operation, with intuitive controls to ensure smooth workflow.

Laminating machines are vital to enhancing product quality, improving packaging durability, and ensuring an efficient production process. Whether used in small or large-scale operations, they provide businesses with a cost-effective solution to achieve high-quality, professional lamination.

Customer's Industry Selection

Tailored Solutions for Different Industries

Our laminating machines cater to various industries, from packaging and printing to textiles and more. By understanding your specific requirements, we offer customized solutions to meet your business needs, enhancing productivity and output quality.

Our Cases

Proven Success Across Diverse Industries

Explore some of our successful cases and see how our machines have helped companies improve their production processes

After-Sales Service We Offer

Comprehensive After-Sales Support for Long-Term Success

We provide full after-sales support to ensure the smooth operation of your laminating machines. From installation and training to spare parts and ongoing maintenance, our team is always ready to assist you.

- 24/7 Support: Access to expert help whenever you need it.

- Fast Spare Parts Delivery: Quick access to essential parts to minimize downtime.

- Ongoing Maintenance: Regular checks and updates to keep machines running at optimal levels.

- Global Support: Engineers available for on-site assistance worldwide.