Intelligent & User-Friendly Operation: One-button start design with a large-screen monitoring system allows single-person independent operation, significantly reducing labor requirements.

Efficient & Energy-Saving Heating: Combined electromagnetic and oil heating modes enable fast heating and high thermal energy utilization, with power consumption as low as 15-20kw/h in pre-coating mode.

Multiple Safety Protections: Fully enclosed hood design combined with automatic fault shutdown function enhances operational safety and meets industrial safety standards.

Precise Film Cutting: Equipped with dual hot knife/chain knife cutting systems, supporting processing of various films (OPP/PET/PVC, etc.) with high cutting accuracy and minimal tail film residue.

Easy to operate, intelligent: one button to start

Energy saving: electromagnetic heating and oil heating are combined, fast heating,high utilization rate ofheat energy

High safety factor: external cover design, safe and reliable operation

Hot knife slitting: special for all kinds ofdifferent film slitting (OPP, PET, PVC) easy toadjust, correction hot knife, high cutting accuracy

Chain knife cutting: specifically designed for cutting various types offlms (OPP, PET, PVC) foreasy adjustment, with a small tail film

|

Max Paper size(W*L) |

920×750(mm) |

|

Min Paper size (W*L) |

300×230(mm) |

|

Paper weight (g/m²) |

≥100,≤500 |

|

Applicable film |

OPP、BOPP 、pre-coated film |

|

The height of the paper pile for feeding |

1150mm |

|

The height of the paper collection stack |

1150mm |

|

Mechanical speed |

0-80m/min |

|

Total power |

45KW |

|

working power |

Glue Coating style: 25-30Kw/h Pre-coating style: 15-20kw/h |

|

Overall Dimensions (L*W*H) |

7400×2280×2600 (mm) |

|

Total weight |

≈8000Kg |

|

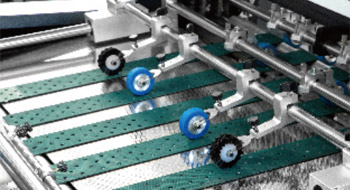

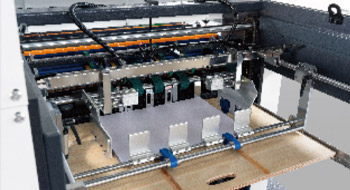

Feeder unit |

① Pre-installed paper, ② Paper replacement without stopping the machine, ③ big screen monitoring ④ High-speed Feida, ⑤ German Beck brand vacuum pump, ⑥ vacuum suction and conveying platform. |

|

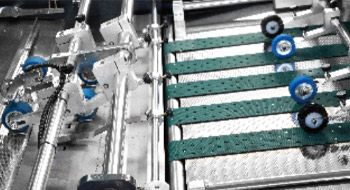

Side Gauge Department |

① Servo side gauge overlap, ② Double-sheet sensing device, ③ Automatic shutdown due to paper shortage |

|

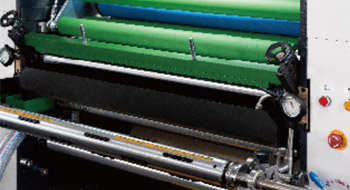

Host Unit |

①φ600 drying roller, φ320 pressing roller, ② Servo coating motor ③ Electromagnetic + heat transfer oil intelligent heating, ④ One-click start of the operating system, ⑤ Film changing hydraulic lifting platform |

|

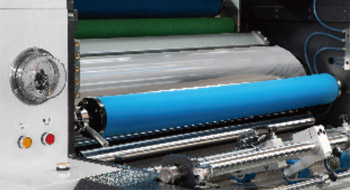

Film Cutting Unit |

① Rotating the cutter for slitting + sandpaper punching for slitting, ② Scissor-type roller for paper cutting. |

|

Paper Collection Unit |

① Wavy paper style collection , ② Neat Paper on three sides ③ Double-sheet waste discharge. |

| Hot cutter type | YS-R920 |

| Chain cutler type | YS-L920 |

| Standard type | YS-S920 |

| Mechanical speed | 20-80m/min |

| Applicable paper gram | 105-500g |

| The maximum available size | 750×920mm |

| The mlnimum avalable size | 230×300mm |

| Total electricity consumption | 45kw |

| Machine weight | 7500kg |

| Machine size | 7400×2280×2600mm |

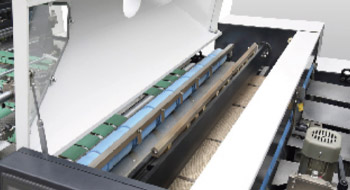

Strong four send and four suction, stable paper feeding; Non-stop paper feeding.

Servo control system, flexible and convenient adjustment.

Adjustment-free negative pressure adsorp-tion, slide rail adjustment, saving time and effort.

The servo motor controls the pull gauge to automatically align, simple operation and precise positioning.

One-button start, easy to operate, equipped with film winding, can achieve independent operation by a single person.

Adopting dual steel roller transmission for gluing, with an accuracy of up to 3g/ m²;

Adopting Teflon treatment to achieve high temperature resistance, non adhesive and other effects.

The laminating roller is combined with elec-tromagnetic heating and oil heating, which heats up quickly and has a high utilization rate of heat energy.

Three-sided paper flushing device, counting function, corrugated paper output, automatic waste discharge, paper blocking and decel-eration.

Equipped with disc knife and abrasive paper wheel for effective slitting of BOPP and OPP films.

For PET film slitting, there are two modes to switch to ensure that different materials and colors can be accurately slit.

Suitable for all films, especially for PET films, aluminized films, etc. It is characterized by fast slitting speed, accurate slitting, small tail film, and can smoothly enter the next process.

Hydraulic lifting.

GET A QUOTE