Automatic varnishing elevates print quality through four core mechanisms: precision application control, multi-layered finish engineering, intelligent curing systems, and functional barrier formation. Unlike manual processes, these automated technologies integrate mechanical precision with material science to enhance both visual aesthetics and physical durability, making them indispensable in modern printing workflows.

1. Precision Varnish Deposition Systems

Enables zone-specific application of matte, gloss, and satin varnishes in a single pass, ideal for creating depth in catalogs or packaging where imagery requires high-gloss contrast against text areas.

Achieves ±5μm thickness control on substrates ranging from 80gsm paper to 600micron plastic, critical for maintaining ink vibrancy on variable data prints like direct mail.

2. Advanced Curing Ecosystems

Utilizes 365nm LED arrays to cure UV oil varnishes at line speeds up to 180m/min, perfect for high-volume packaging runs where abrasion resistance is critical.

3. Functional Coating Capabilities

Applies nano-composite varnishes that reduce oxygen transmission by 92%, extending shelf life for food packaging while maintaining print clarity.

4. Color Preservation Technologies

Automated feedback loops in UV Oil Varnish systems adjust varnish laydown to maintain ΔE<1.5 color accuracy across different substrates.

HALS (Hindered Amine Light Stabilizer) additives in Automatic UV Varnishing processes prevent UV-induced degradation, keeping outdoor signage vibrant for 3+ years.

Industry Applications and Cross-disciplinary Impact

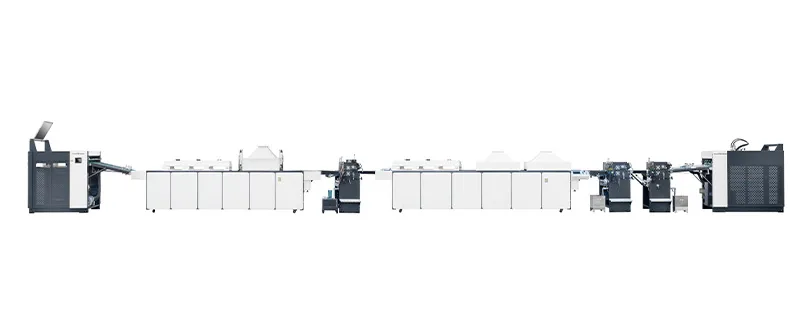

Modern Automatic UV Varnishing Machines now integrate:

These advancements ensure that whether producing a run of 50 luxury invitations or 500,000 retail boxes, the print quality remains consistent—with varnish layers that not only enhance visual appeal but also serve as functional barriers against environmental stressors.

Automatic varnishing technologies—from the Three Heads Coater to the Single Infrared Drying Machine—revolutionize print quality by merging precision application with intelligent curing systems. These solutions transform prints into durable, visually striking assets that:

By prioritizing both aesthetic appeal and functional resilience, automatic varnishing sets new standards for professional printing excellence.

GET A QUOTE