Automatic film laminators are essential tools for businesses in printing, packaging, and manufacturing, offering speed, precision, and consistency in applying protective or decorative layers to materials. Whether you’re working with a film laminating machine, a window lamination machine, or a high-speed automatic thermal laminating machine, mastering the operational process ensures optimal results. This guide walks you through the steps to use an automatic film laminator effectively, while highlighting key applications and compatible machinery.

Before starting, ensure your substrate (e.g., paper, cardboard, or film) and laminate film are compatible with your machine.

1. Material Compatibility: Check the laminator’s specifications for supported thicknesses and materials. For example, a roll thermal laminating machine typically works with polyester (PET) or polypropylene (PP) films.

2. Trim Excess Edges: Trim substrates to the desired size, especially for specialized tasks like window lamination machine applications, where precise alignment is critical for transparent "window" effects.

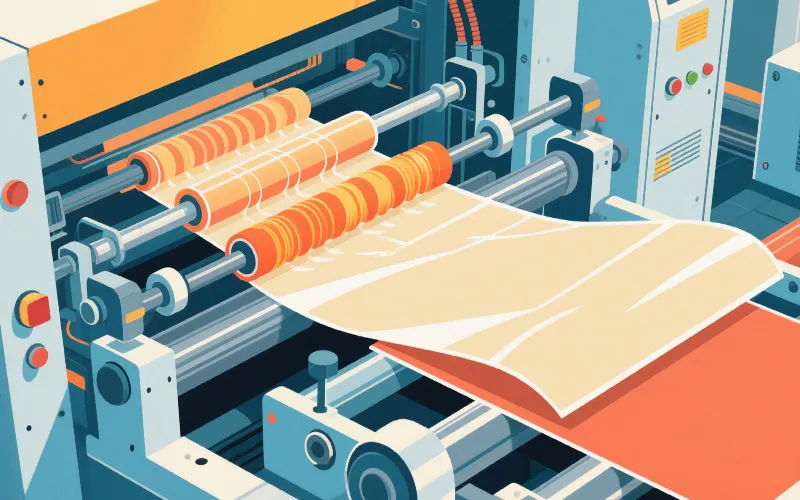

Most automatic thermal laminating machines feature dual-roll systems for top and bottom films.

1.Mount the Film Rolls: Load the laminate rolls onto the machine’s unwinding shafts, ensuring the adhesive side faces the substrate.

2.Thread the Film: Feed the film through the machine’s guide rollers, following the manufacturer’s diagram.

3.Load the Substrate: Place your material into the feeding tray. For delicate items, use a carrier sheet to avoid jams.

Adjust settings based on your material and film type:

*Temperature: Thermal laminators require heat to activate the adhesive. For example, a roll thermal laminating machine may need 90–120°C for PP films, while thicker materials might require higher temperatures.

*Speed: Match the conveyor speed to material thickness. Thicker substrates or intricate designs (e.g., window laminates) often require slower speeds for even adhesion.

1.Preheat the Machine: Allow the laminator to reach the set temperature.

2.Automatic Feeding: Activate the conveyor system. The machine will pull the substrate and film through heated rollers, bonding them seamlessly.

3.Monitor Output: Check the first few laminated sheets for bubbles, wrinkles, or misalignment. Adjust settings if needed.

*Cooling: Let laminated materials cool before cutting or stacking to prevent warping.

*Trimming: Use a guillotine cutter to remove excess film, particularly for window lamination machine outputs where precision is vital.

*Maintenance: Clean rollers regularly to avoid adhesive buildup, ensuring consistent performance for both film laminating machines and automatic thermal laminating systems.

*High-Volume Projects: Opt for an automatic thermal laminating machine with adjustable speed and temperature presets for efficiency.

*Specialty Designs: A window lamination machine is ideal for packaging with transparent sections, such as food boxes or luxury product labels.

*Versatility: Roll thermal laminating machines suit diverse materials, from posters to industrial films.

Automated systems reduce human error, enhance throughput, and deliver uniform quality—critical for industries prioritizing aesthetics and durability. By understanding your machine’s capabilities, whether it’s a standard film laminating machine or a specialized automatic varnish coating machine, you can maximize ROI and meet client demands effortlessly.

Mastering your automatic laminator unlocks endless possibilities for creative and functional finishes. Invest in training and routine maintenance to keep your equipment—and your business—running smoothly.

GET A QUOTE